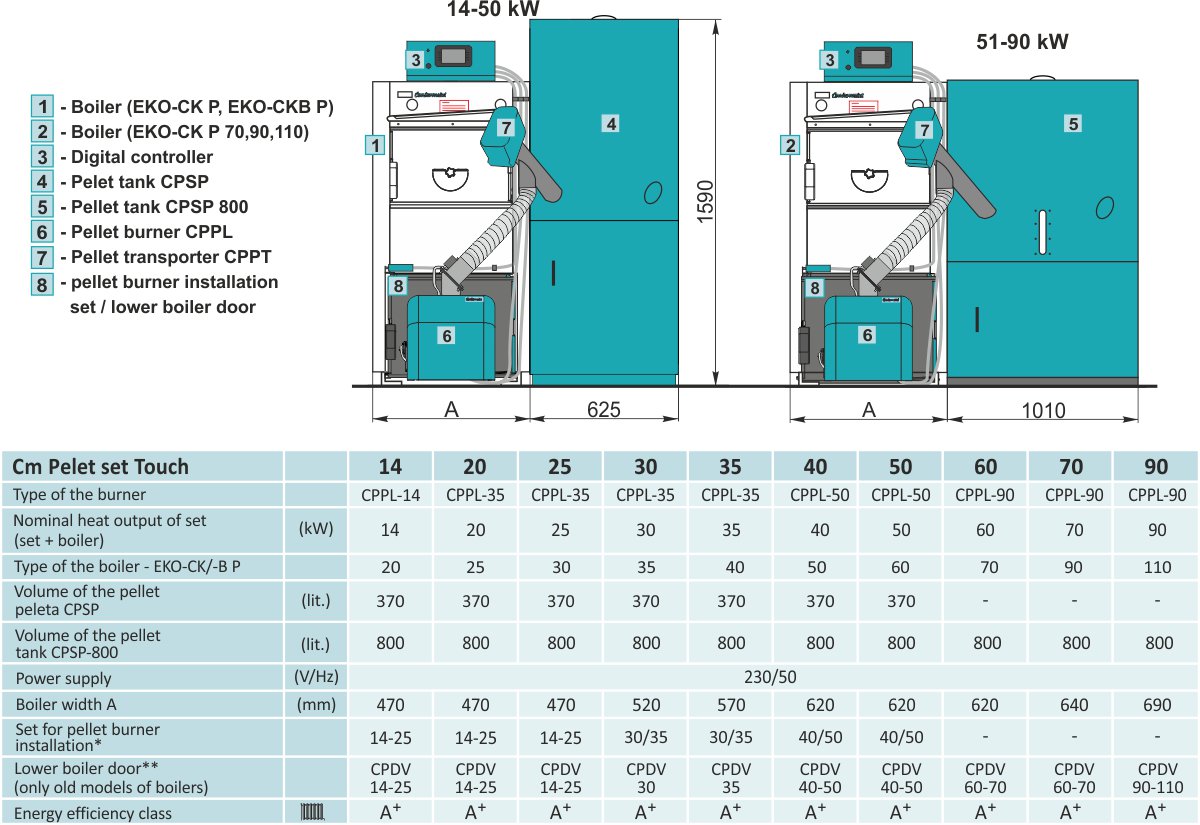

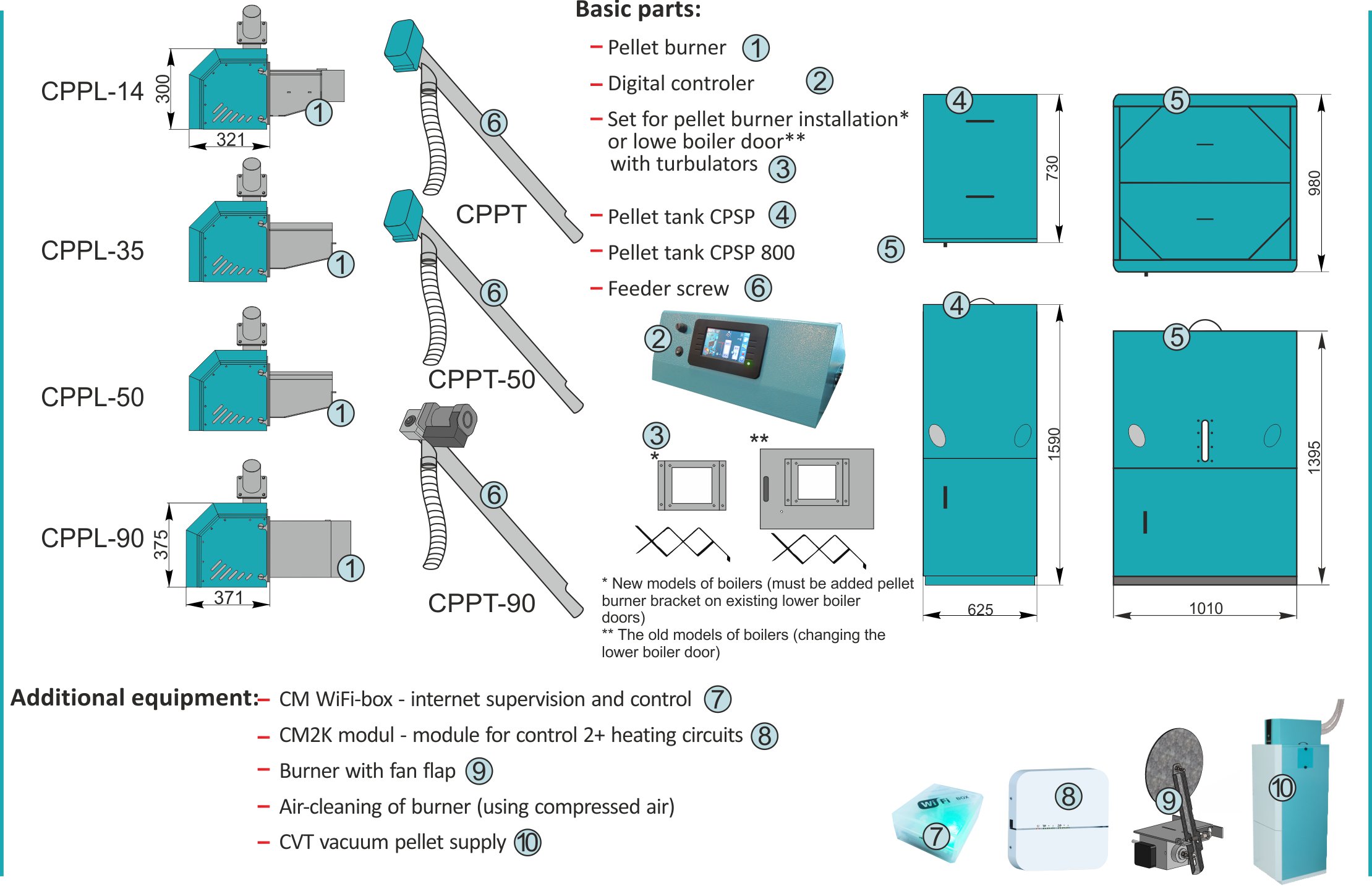

PRODUCT CHARACTERISTICS

FUEL CHARACTERISTICS – WOOD PELLET:

- Wood pellet is a renewable fuel, and therefore ecologically acceptable.

- It is made out of wood bio-mass scraps extruded into pellets by special machinery.

- Pellets are delivered in various ways: in bags (15 kg or 1000 kg), or as bulk into large, possibly underground, storage tanks (4 – 15 m3) or into basement spaces or sheds.

- Recommended specification for pellets for Cm Pelet-set feeding:

- – heating value >= 4,9 kWh/kg (17,5 MJ/kg)

- – diameter = 6 mm

- – max. length = 50 mm

- – max. humidity = 12%

- – max. ash = 1,5%