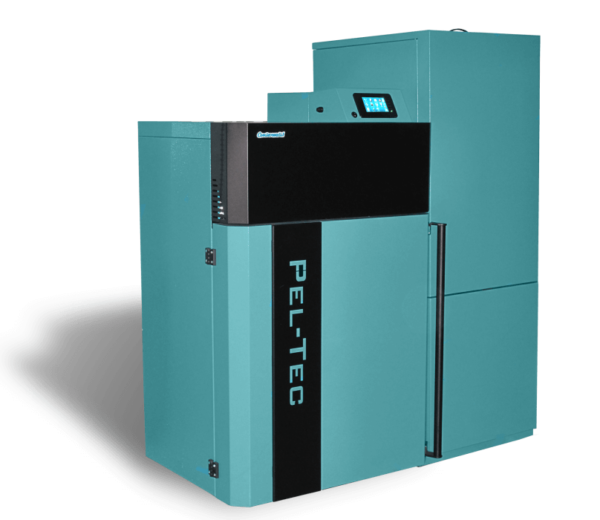

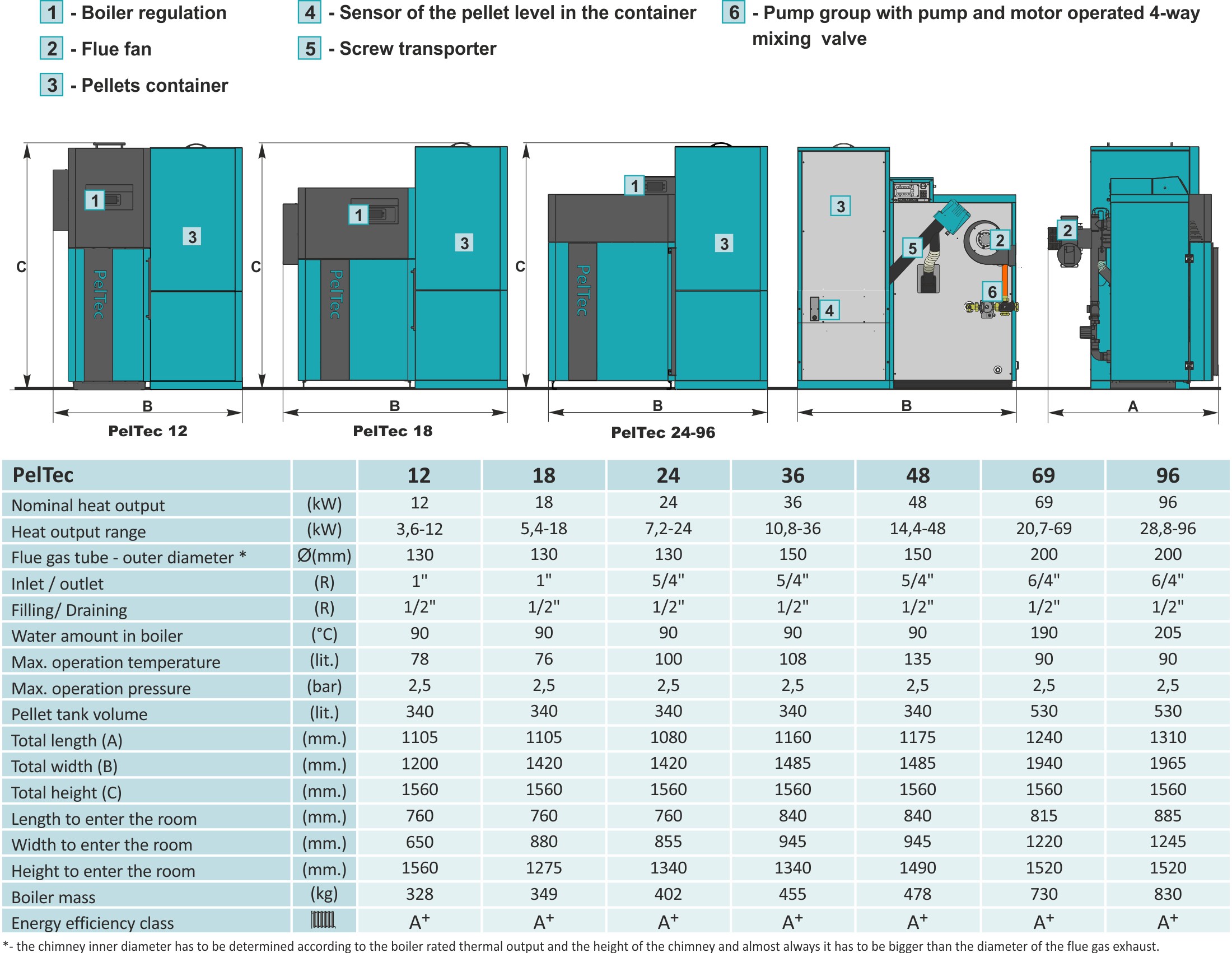

PRODUCT CHARACTERISTICS

INTERNET SUPERVISION AND PelTec/PelTec-lambda MANAGEMENT (additional equipment)

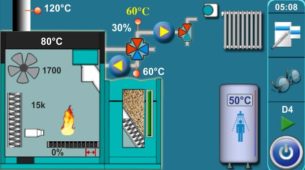

Remote access

Access with your smartphone, tablet, or computer. Read the value through an intuitive graphical interface.

Supervision

Displays the amount of pellets in the tank. Temperature monitoring, boiler online ignition and parameter change.

Connectivity options

Connecting to a home WiFi internet network.

Analytical data

History of temperature, graphs, error messages, warnings.

Detailed statistics

Detailed statistics on the operation of individual boiler elements.