PRODUCT CHARACTERISTICS

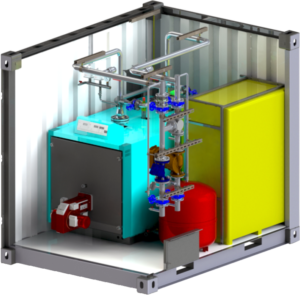

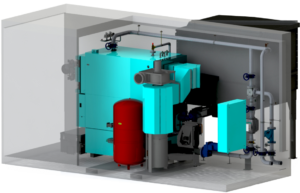

Internal detail of the container boiler room with a liquid fuel firing boiler installed.

Internal detail of the container boiler room with a liquid fuel firing boiler installed.

Container boiler rooms fired with oil - CKK-U 18 - 2.100 kW

Delivery options:

- Standard containers up to 40ft or custom made

- Nominal heat output: 18 – 2100 kW

- Hot water boiler with oil burner

- Oil tank connection

- All necessary safety elements

- Basic boiler controller or digital controller according to outdoor temperature

- Installed hydraulic separator and/or DHW tank

- Insulated piping, preparation of the boiler water, elements according to the customer’s needs

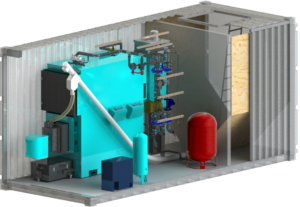

Container boiler rooms fired with wooden pellets - CKK-P 12 - 320 kW

Delivery options:

- Standard containers up to 40ft or custom made

- Nominal heat output: 12 – 320 kW

- Hot water boiler with pellet burner, automatic boiler cleaning and ash removal from the boiler

- Pellet tank with alert in the same or in a separate container

- All necessary safety elements

- Insulated piping, preparation of the boiler water, elements according to the customer’s needs

- Basic boiler controller or digital controller according to outdoor temperature

- Installed hydraulic separator or accumulation tank and DHW tank

Container boiler rooms fired with wooden chip / wooden pellets - CKK-S 160 - 340 kW

Delivery options:

- Standard containers up to 40ft or custom made

- Nominal heat output: 160 – 340 kW

- Hot water boiler with moving grate or retort, automatic boiler cleaning and ash removal from the boiler

- Wood chips tank in a separate container or an outer tank

- All necessary safety elements

- Insulated piping, preparation of the boiler water, elements according to the customer’s needs

- Installed hydraulic separator or accumulation tank and DHW tank.

Installing a full sized permanent boiler room in brand new premises, while for example only a few flats are inhabited, is hardly economically practical because of relatively low utilization. Therefore in the early stages it is preferable to connect a temporary boiler room until the whole building is technically approved and completed. Alternatively, during road construction or other major projects, there is also a need to provide warm offices and other facilities for personnel. A temporary boiler room for such purposes is a perfect solution.