top_left_eng

- Home

- Products

- Boilers

- Wood pellet stoves and thermostoves

- Solar technology

- Accumulation tanks and boilers

- Other

- About us

- Support / Service

- DOWNLOAD

- Contact

- Authorised serviceman

- Language

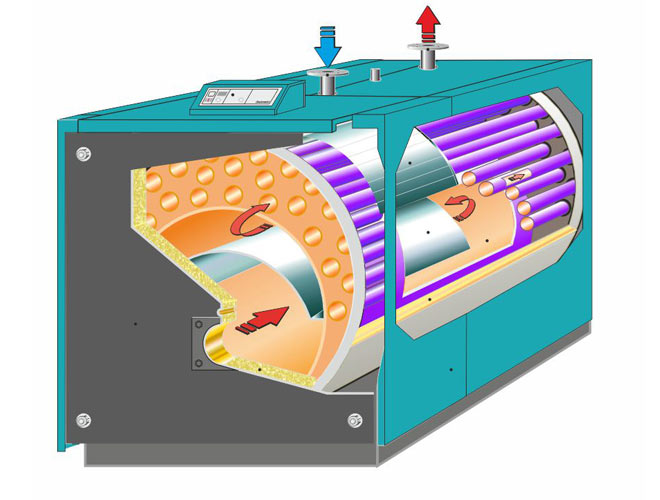

This product is a synthesis of modern technologies and is presented in high quality materials ready for simple and easy assembly and operation. The fully developed and tested technical solutions applied assure these boilers are safe and reliable. The triple-pass flue gas flow system is a key element of their low energy consumption. The wide range of available control devices, as additional equipment, enables the customer to benefit from a fully automatic direct or remote controlled heating center.

Built-in turbulators allow better heat transfer from flue gas to boiler water.

A special feature is the exceptional thermal insulation of the boiler.

(Obligatory additional equipment). From 2020., advanced CUPREG-Touch control is available.

Delivered in parts that allows easy transportation and installation of the boiler.